[White Paper] Next Generation Multi-Fiber Ferrule Using 165 Micron Pitch Optical Fiber Ribbon

Fujikura Ltd has released a new White Paper on Next Generation Multi-Fiber Ferrule Using 165 Micron Pitch Optical Fiber. Please find below for the abstract and the download link.

16-fiber ribbon and 12-fiber ribbon

MT-16 and MT-12 ferrule

Next Generation Multi-Fiber Ferrule Using 165 Micron Pitch Optical Fiber

Hirotaka Asadaa, Darrell Childersb, Mike Hughes*b, Takaaki Ishikawaa, Sharon Lutzb, Dirk Schoellnerb, Kansei Shindoa, Yasuyuki Wadaa

aFujikura Ltd, 1-5-1, Kiba, Koto-ku, Tokyo 135-8512, Japan;

bUS Conec Ltd, 1138 25th Street SE; Hickory, NC 28601.

ABSTRACT

The continued acceleration of switching capacity and link transmission bandwidth is driving the need for new connectors in next generation optical networks. With 25.6Tb switch ASICs available in 2020 [1], only two years after the introduction of 12.8Tb switching, the industry is now looking to radical new architectures to achieve 51.2Tb switching, including the advent of optics integrated or co-packaged with ASIC technology. The standard 250μm pitch used in multi-fiber ferrules with 125μm cladding diameter optical fiber is physically too large to support the quantity of optical lanes that will be coupled inside the coming switching platforms.

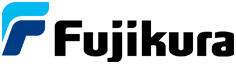

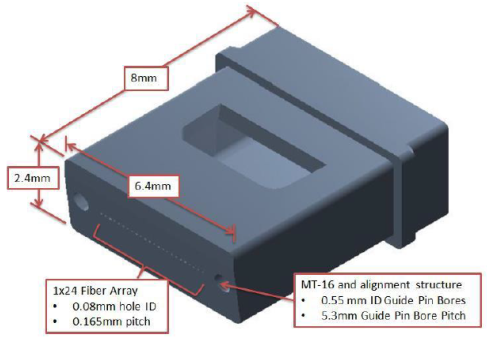

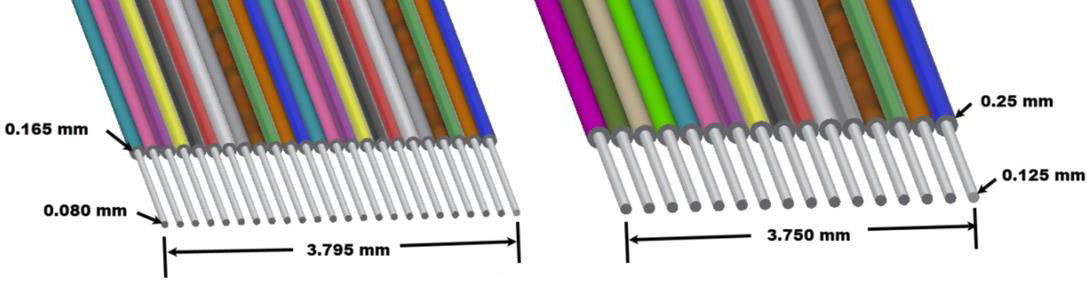

This paper describes a next generation MT-style ferrule designed for fibers with 80μm cladding diameter on a pitch of 165μm. By decreasing the pitch from 250μm to 165μm, up to 24 fibers can be placed in a single row between the pins of the MT-16 alignment structure. This tighter pitch enables higher fiber densities coupled directly to or in the proximity optical Tx/Rx photonic tiles.

Endface geometry models combined with connector mating normal forces are based on the traditional 250μm pitch of MT-style ferrules. Fiber tip radii, fiber tip coplanarity, ferrule surface endface angles relative to alignment pin bores were measured empirically and documented on the new design. Varied topologies were combined with different mating forces demonstrating effective physical contact for the new ferrule. Mated pairs were monitored for attenuation changes during exposure to industry standard uncontrolled environment temperature cycling. Subsequent specifications for future end face geometry and mating spring force requirements are proposed.

Keywords: MT Ferrule, 80 micron, 165 micron, MT-16, MT-24

Download the white Paper here.

© 2021 Society of Photo Optical Instrumentation Engineers (SPIE). One print or electronic copy may be made for personal use only. Systematic reproduction and distribution, duplication of any material in this paper for a fee or for commercial purposes, or modification of the content of the paper are prohibited. http://dx.doi.org/10.1117/12.2578649