MENUMENU

LAZERMaster LZM-100 Series Laser Splicing System

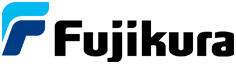

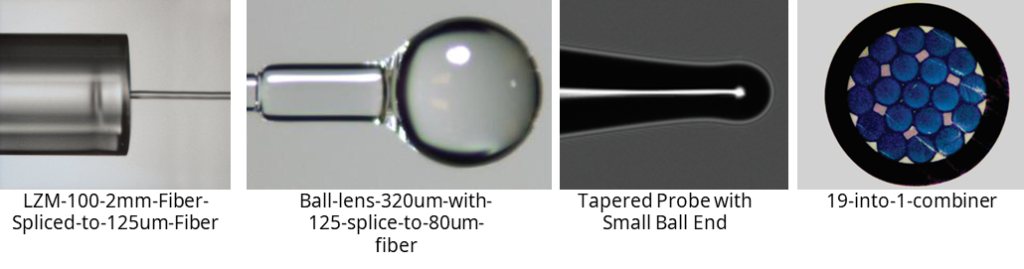

AFL’s LAZERMaster® is a series of glass processing and splicing systems that uses a CO2 laser heat source rather than electrodes, ensuring repeatable performance and low maintenance, and eliminating electrode or filament maintenance and instability. Splicing or adiabatic tapering (to create mode field adapters or pump combiners) can be performed with glass diameters of 2 mm or more. The high resolution optical analysis system works in conjunction with on-board firmware for fully automatic splicing, tapering and other glass shaping processes.

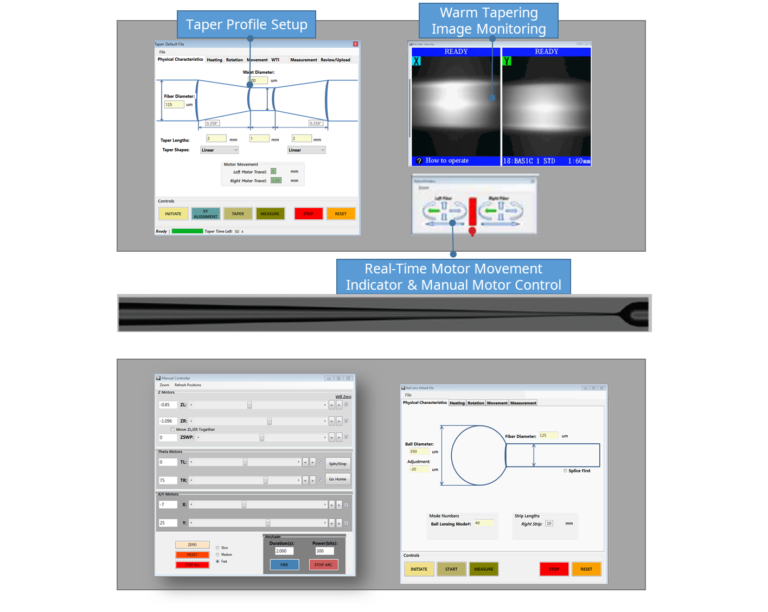

High precision glass processing is enabled by the intuitive and user- friendly on-board firmware, virtually identical to that of the Fujikura FSM-100 series. Operations may be performed manually or by PC control. The FPS (Fiber Processing Software) PC control GUI (Graphical User Interface) is supplied with the LZM series to provide additional features, greater flexibility, and finer control. The FPS GUI may be used on a PC chosen by the customer. Customers can also create proprietary PC control algorithms using a complete set of PC control commands.

| Model / Specification |

LZM-100 |

LZM-125M+ |

LZM-125P+ |

LZM-125A+ |

| Appearance |  |

|

||

| PM Fiber Splicing | Yes (Option) | No | Yes | |

| End View fiber observation system | Yes (Option) | Yes | ||

| Taper Length | Up to 130 mm | Up to 34 mm | ||

| Fiber Ablations & Shaping | No | No | No | Yes |

- Features

- Specifications

Applications for each model

| Model |

LZM-100 |

LZM-125M+ |

LZM-125P+ |

LZM-125A+ |

| Fiber Ablations & Shaping | Yes | |||

| Combiner Production | Yes | |||

| Long Period Grating Manufacturing | Yes | |||

| Tapering (maximum length) | 130 mm | 34 mm | ||

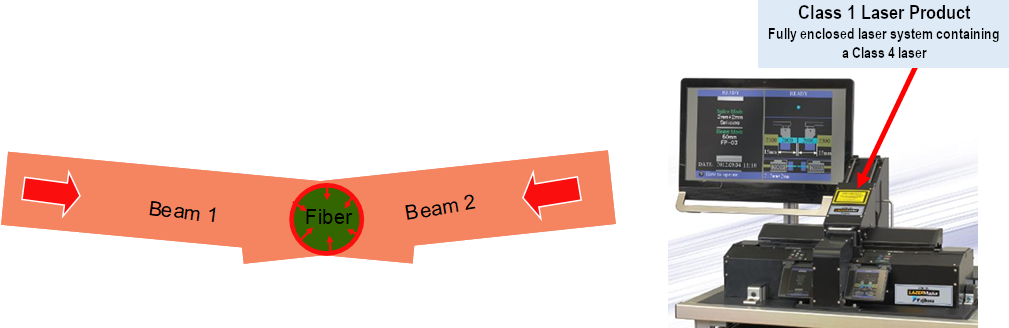

| Ball Lens Production | Yes | Yes | Yes | |

| LDF Splicing | Yes | Yes | Yes | Yes |

| Different Diameter Fiber Splicing | Yes | Yes | Yes | Yes |

| Endcap Splicing | Yes | Yes | Yes | Yes |

| Capillary Collapsing onto fibers | Yes | Yes | Yes | Yes |

| Axicon Lens Production | Yes | Yes | Yes | Yes |