MENUMENU

ELiMENT™ MDC CONNECTOR

Brand :

Telecommunications

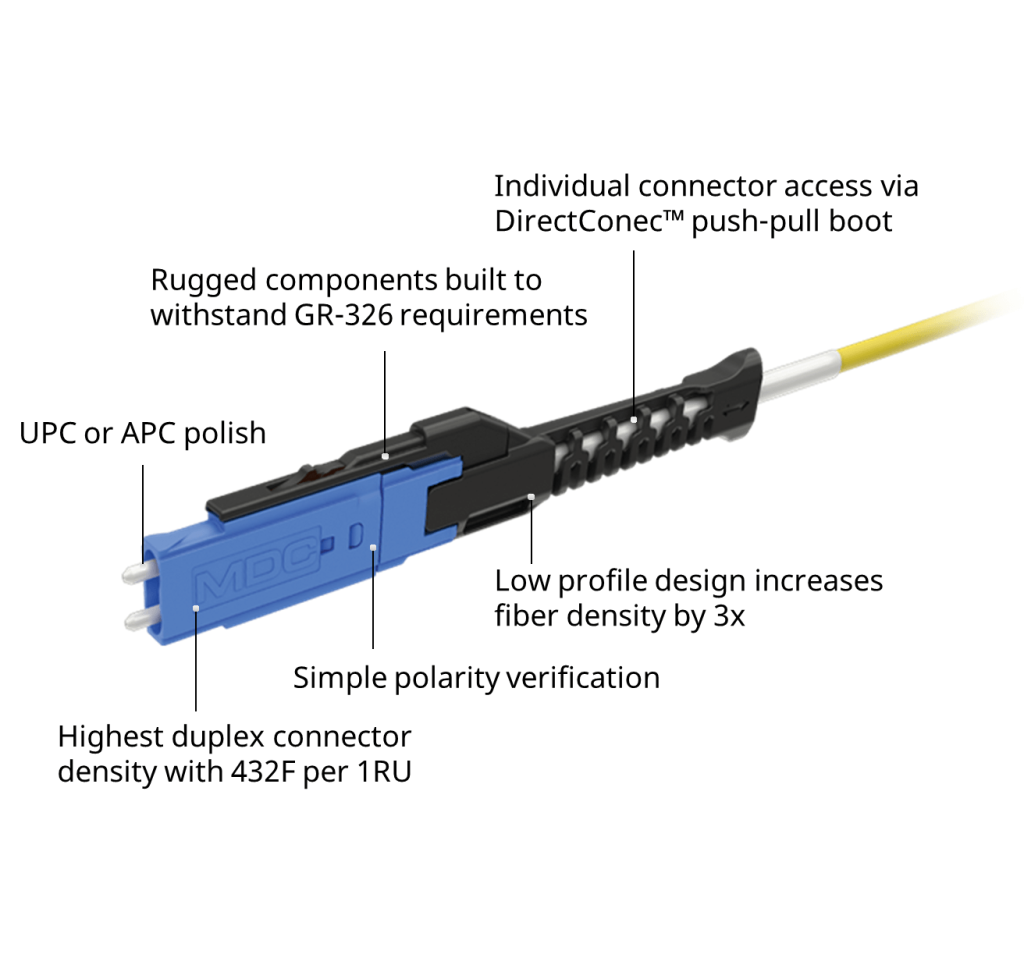

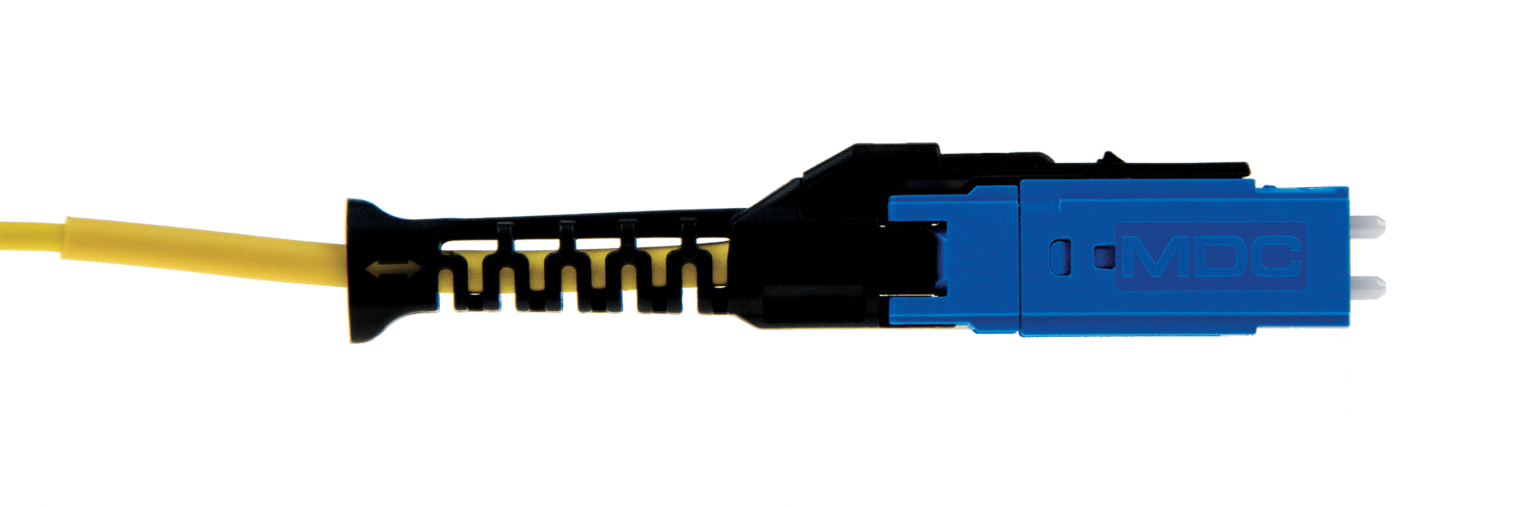

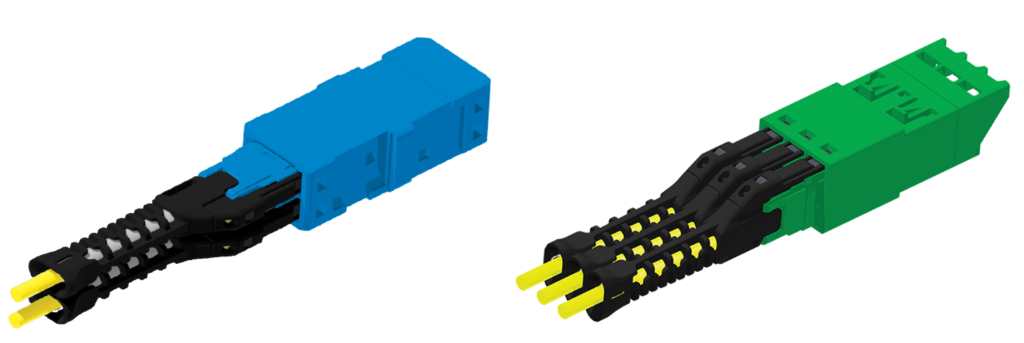

Fujikura’s ELiMENT™ MDC connector licensed from US Conec is a Very Small Form Factor (VSFF) duplex optical connector designed for termination of multi-mode and singlemode fiber cables up to 2.0mm in diameter. The MDC connector is manufactured with proven 1.25mm ferrule technology used in industry standard LC optical connectors. Individual connector access in the most extremely dense connector environments is easily accomplished using the revolutionary DirectConec™ push-pull boot technology.

New Applications Require a Reduced Format Connector

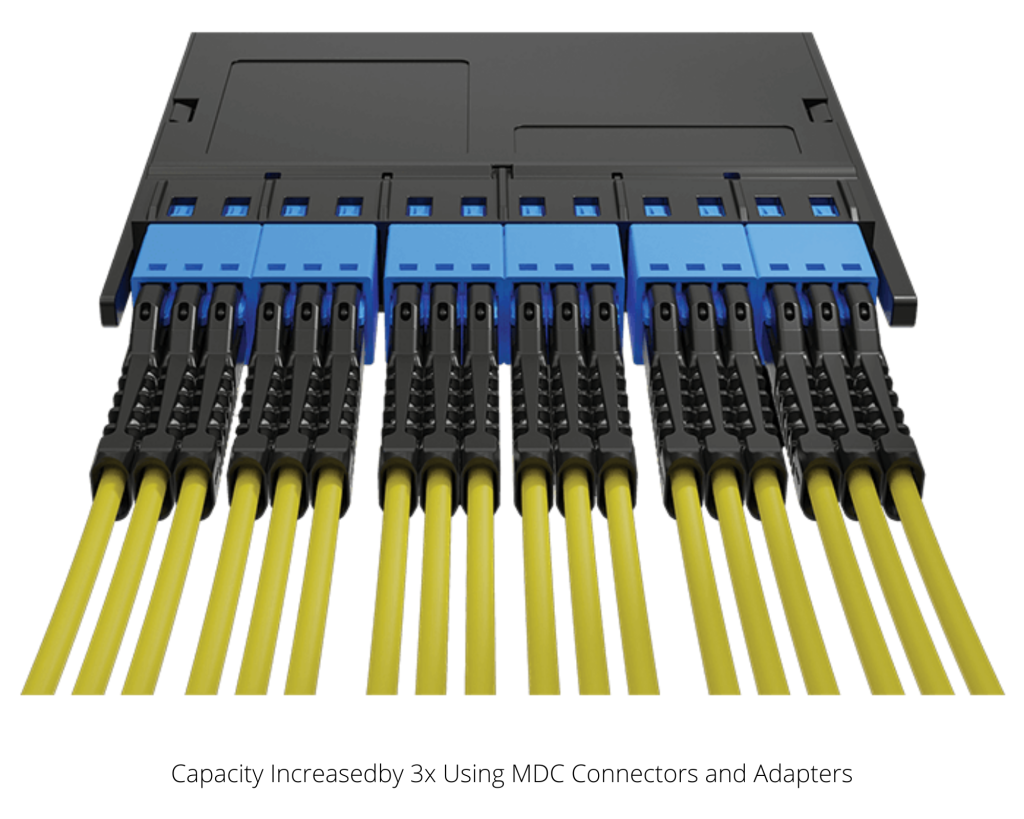

Increasing connector density at the module/panel minimizes required hardware, leading to reduced capital and operational expense. Currently, a one Rack Unit (RU) housing is limited to 144 fibers using LC Duplex connectors and adapters. The smaller MDC connector increases the connector density by 3x, providing up to 432 fibers in the same 1 RU space.

Multiple emerging transceiver Multi-Source Agreements (MSAs) have defined port breakout architectures that require a duplex optical connector with a smaller footprint than the LC connector. The reduced size of the MDC connector will allow a single array transceiver to accept multiple MDC patch cables which are individually accessible directly at the transceiver interface. The new format will support four individual MDC cables in a QSFP footprint and two individual MDC cables in an SFP footprint.

Carrier Grade Performance

Although the MDC connector is almost half the size of an LC connector with twice the number of ferrules, it’s rugged housing, high-precision molding and engagement length allow it to exceed the same Telcordia GR-326 requirements as the LC connector, including the extremely demanding Proof and TWAL tests.

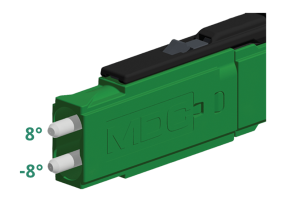

MDC APC Connectors

MDC APC connectors are available for high density duplex connector applications requiring a very low reflectance. The unique opposing angled ferrule connector design allows for simple and effortless polarity reversal in the event the system polarity is not as expected.

MDC APC connectors are available for high density duplex connector applications requiring a very low reflectance. The unique opposing angled ferrule connector design allows for simple and effortless polarity reversal in the event the system polarity is not as expected.

Maintaining Duplex Connector Accessibility with DirectConec™ Push-Pull Technology

MDC connectors with DirectConec™ push-pull boot technology allows installation experts to easily insert and extract the connector in tighter, more confined spaces without affecting neighboring connectors. The flexible boot maintains proper bend radius for cable routing and will not buckle during connector insertion and extraction.

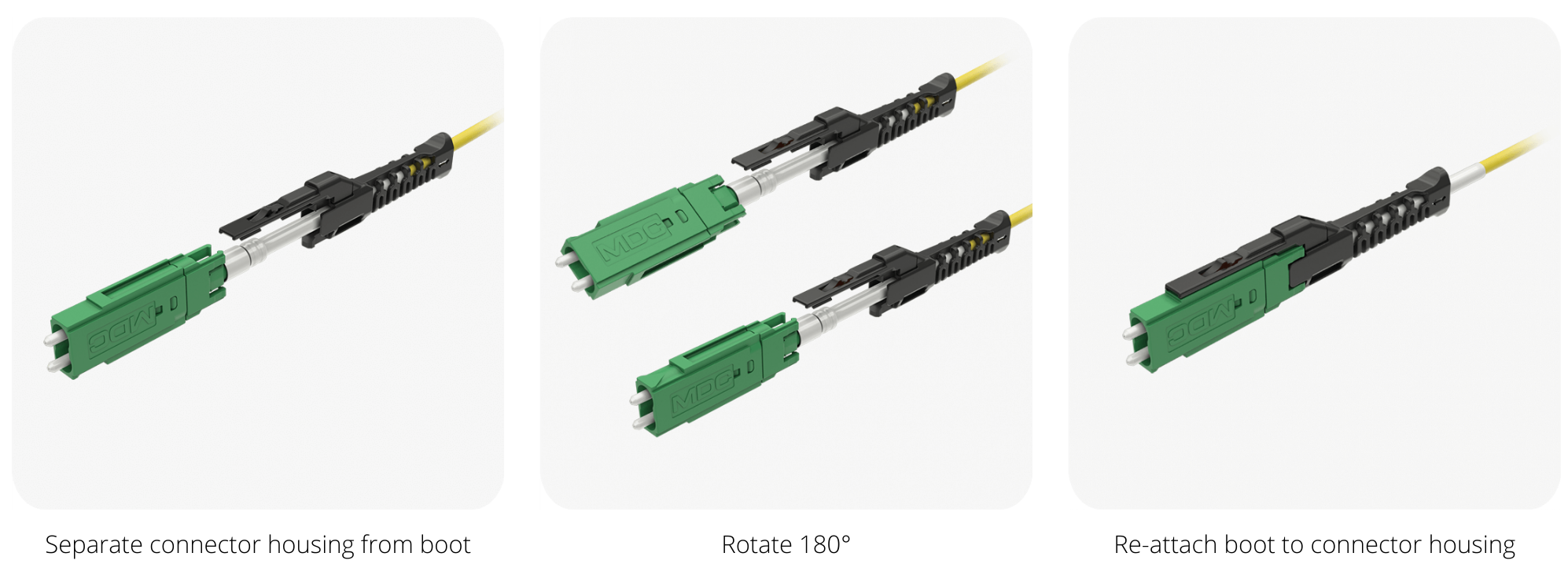

Quick and Simple Polarity Reversal

The polarity reversal of the MDC connector is effortless and does not expose or twist delicate fibers during the process. To change polarity, pull the boot from the connector housing, rotate the boot 180 degrees, and re- assemble the boot assembly back onto the connector housing. Polarity marks on the top and side of the connector and the MDC logo provide notification of reversed connector polarity.

Polarity Reversal Process:

Ever-Increasing MDC Ecosystem

US Conec partners with industry leading vendors to develop components and equipment necessary to improve the installer and end-user experience with the following solutions:

Multiple adapter variants

Multiple adapter variants- Aggregation solutions

- Polishing equipment

- Test equipment

- Inspection scopes

- Interferometry

Click here for MDC Connector solutions and accessories.

- Features

- 3x fiber cabling density over LC connectors, providing 216 duplex connectors (432 fibers) within 1 RU

- DirectConec™ push-pull boot for effortless connector insertion and extraction

- Simple polarity reversal with no exposed fibers

- Meets IEC Attenuation Grade B random mating requirements (0.12 dB mean, 25 dB maximum for ≥ 97% of the connectors)

- Telcordia GR-326 and TIA-568 compliant

- Designed for cables up to 0mm OD

- Multi-mode, Singlemode and Singlemode APC available